Moog

Tapping artificial intelligence to improve materials engineering

Moog, a global aerospace and engineering company, relies on material components and parts that are lightweight, durable and flawless. Through an ongoing partnership with UB, Moog partnered with research experts, talented students and teams trained on specific technologies to develop specialized imaging capabilities to determine the quality of DMLS additive parts. Moog also worked with UB to use software algorithms to discern the feasibility of using additive manufacturing for a part – as a Yes, No, Maybe with Changes outcome.

How Moog collaborates with UB

CHALLENGE & OPPORTUNITY

Manufacturing quality control

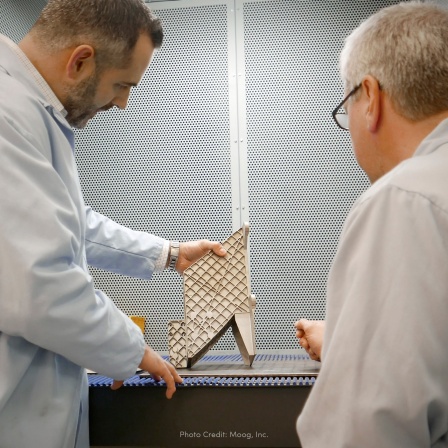

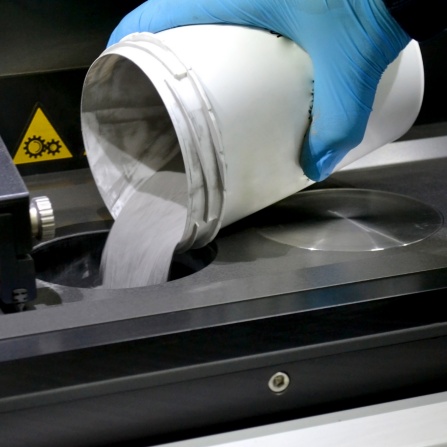

The most important considerations in manufacturing elements for the aerospace and space industries are always cost, weight and reliability. Many parts are made using a process called metal additive manufacturing, a relatively new, largely digital method of automated metal part manufacturing using metal powder or metal wire as raw material. While the process provides more complex parts and significantly reduces material waste, production steps, on-hand inventory and the amount of distinct parts needed for an assembly, sample parts must be routinely inspected for quality under a microscope or using X-ray Computed Tomography. This is tedious, time-consuming work.

SOLUTION & OUTCOME

Machines aid inspections

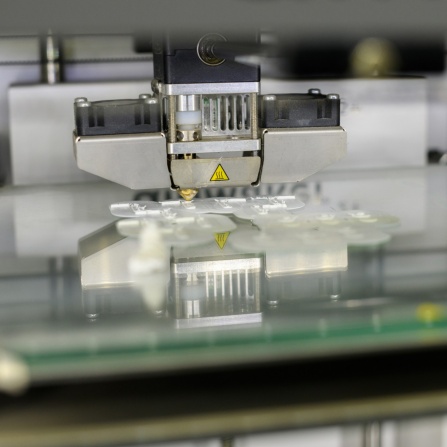

Moog leveraged their relationship with UB and worked with experts in machine learning and image recognition to augment the human centered inspection of metallurgical sampling of laser welded additive manufactured metal parts. Simply put, the computer ‘learns’ the difference between three process outcomes in additive manufacturing, allowing the machine to inspect metal additively manufactured parts. The result was a developed, novel, deep learning-based machine learning computational pipeline (software) to classify the 3D-printing images automatically into various categories, such as over-melt, under-melt and just right. By processing 3D printing image data at a previously impossible scale, this project created a foundation for discovering new connections between metallic 3D printing and materials properties.

UB SUPPORT

Practical application of ongoing research

UB research experts and assistants partnered with the company on multiple R&D projects to address a substantial need in additive design and manufacturing processes by developing a novel fabrication feasibility framework. Five categories of assessments were used which qualitatively and quantitatively evaluated fabrication feasibility for additive manufacturing. Now, the capability of a part to be 3D printed is determined prior to the actual printing. Such an analysis can support rapid assessments of whether or not to select additive manufacturing as the fabrication strategy. As a result, it can lead to a reduction in errors and printing failures and also avoid ineffective use of available resources. The company is now working on implementing these image recognition activities into several active projects where convolutional neural network-based inspection of metal additive manufacturing parts is present. Joint efforts continue towards further development of the software, including the development of a metal predictive model, machine learning to facilitate geometric re-design and more comprehensive build orientation. Moog has hired hundreds of UB engineering graduates and interns to date.